Today we feel incredibly honoured to feature Oliver Henry on the Wovember blog. Known to Shetland friends and locals as “Ooey Ollie” (ooey = woolly), Oliver has been sorting and grading wool at Jamieson and Smith for almost 45 years. In so many respects, Oliver really is the Shetland Woolbrokers, and what he doesn’t know about wool sorting isn’t worth knowing. Thanks so much for sharing your woolly thoughts, Oliver!

Wool is . . . by Ooey Ollie

Wool is different things to me at different times of the year.

In the summer, wool is hearing the distinct engine noise of a 4 X 4 pulling up outside the wool store, covered in mud and usually connected to an Ifor Williams trailer, full of wool.

The next bit involves greeting the crofters and farmers at our big green doors and dragging in the wool bales before weighing them in, and remembering to mark on the grading number that allows us to track our wool right through processing. We store the bales by piling them up to the roof, usually pulling them up by hand. This gets harder each year as time is catching up with me!

(Oliver drags in bales, and starts to grade. Photo by Billy Fox)

(Oliver drags in bales, and starts to grade. Photo by Billy Fox)

On opening the bales to start grading I have to take a deep breath – how the wool is presented can have a serious effect on my mood!

If the wool is properly presented, all rolled up with the neck displayed, it is a pleasure. However, if it is packed in heels overhead, it becomes a hard chore, especially when packed too tight. Shetland wool can lack uniformity of quality and staple length, so seeing the best part of the fleece at a glance makes the grading much easier to give the best price back to our local wool producers.

(Oliver demonstrating sorting (he doesn’t have his gansey and hat on so it can’t be the real thing!). Photo by Billy Fox)

(Oliver demonstrating sorting (he doesn’t have his gansey and hat on so it can’t be the real thing!). Photo by Billy Fox)

In the Winter the wool store doors are firmly shut to keep out the storms (we’re being battered today).

This is the time of year when we retreat inside to sorting the various qualities of wool. Sorting involves unrolling each one of our coloured fleeces and separating fine from rough, with four grades in between. These different qualities of wool each have their own special use: rough for hardwearing carpets and the finest, most silky parts for our fine lace yarns.

(Winter’s work – coloured Shetland wool waiting to be sorted. Photo by Jared Flood)

(Winter’s work – coloured Shetland wool waiting to be sorted. Photo by Jared Flood)

Sorting is both challenging and rewarding. Sometimes a coloured fleece will take the breath from you when you least expect it to, like when you come across a rare marking or a beautiful crimp. But the best bit of my job is seeing the fruits of our efforts come back into the wool store transformed into everything from yarn to scarves to carpets to beds.

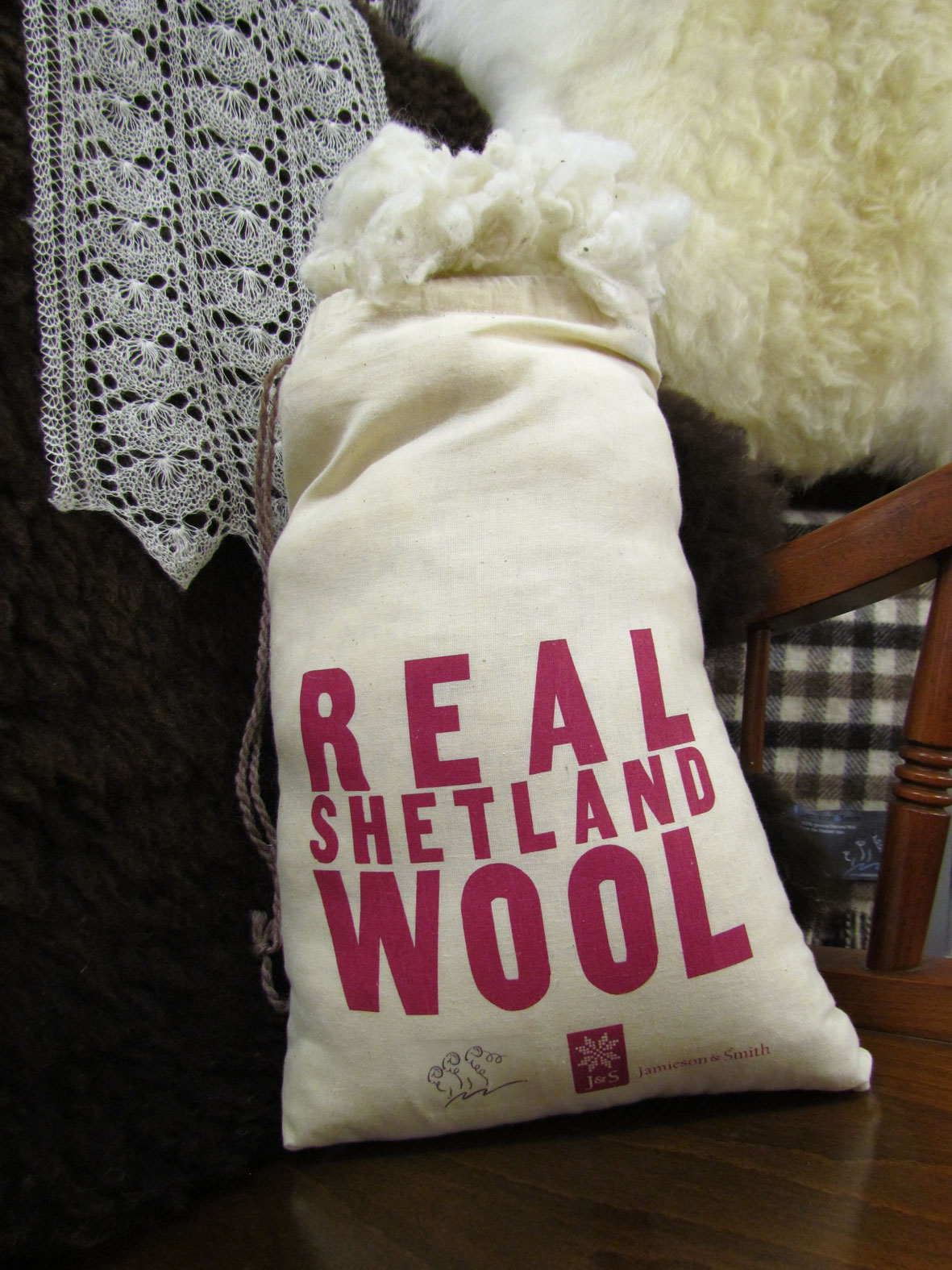

(Finished wool products. Photo by Sarah Laurenson)

(Finished wool products. Photo by Sarah Laurenson)

I think that telling the story of our wool – and the heritage and culture, people and communities behind it – is one of the most important bits of my job. It’s important for the future of the industry in Shetland, and for a new generation of budding crofters and farmers, to tell people why Shetland wool is so special (and has been for centuries) and what an honour it is to be involved with one of the finest natural fibres in the world.

We at Wovember say: hear, hear!