This evening we’re thrilled to bring you a post by John Arbon who runs a wool mill in North Devon. As well as producing textile products – socks, fibres, hand-knitting yarns – John Arbon creates custom spun yarns for customers like Rachel Atkinson with her wondrous Daughter of a Shepherd Yarn. He’s also developed textile products that bring out the best qualities of the sheep local to him – the Exmoor Blueface – and can often be found at wool and fibre festivals all over the UK along with his wife and business partner, Juliet. With his practical knowledge of working mill machinery, his collaborative approach to wool work and his deep knowledge of different fibre types, we felt he’d be ideally placed to talk through some of the complexities of the EU legislation that we shared yesterday. This is a long post but it’s vitally important because it provides a perspective on the same issues we address in our petition from within the working wool industry. John also reveals how the current EU legislation on textiles is set up to support the needs of large textile businesses rather than the interests of small producers and consumers of wool. Get a cup of tea and settle in for an enlightening read.

Wool Labelling: Deciphering the Legislation

I produce and process a number of wool products for both wholesalers and retailers. It is important that my products are clearly and accurately labelled, informing purchasers of their nature and content. Indeed, there is European legislation for the labelling and marketing for woollen textile products. Unfortunately, there is confusion and misunderstanding about correct labelling to which this legislation contributes. The legislation in question is:-

EU labelling legislation

RegNo. 1007/2011

Textile Fibre Names & Related Labelling

Regulation (EU) No 1007/2011 of the European Parliament and of the Council of 27 September 2011 on textile fibre names and related labelling and marking of the fibre composition of textile products and repealing Council Directive 73/44/EEC and Directives 96/73/EC and 2008/121/EC of the European Parliament and of the Council Text with EEA relevanceWebsite Link: http://eur-lex.europa.eu/legal-content/en/TXT/?uri=CELEX%3A32011R1007

I first became aware of the legislation in 2010 when I was warned that I wouldn’t be able to state on my labelling what breed of sheep was in my product, that it would have to be labelled generically as WOOL, and that if I didn’t do this I would be fined. However, in reality this would not seem to be the case! The legislation does in fact allow any manufacturer, producer or retailer to state the breeds used, complete with a percentage breakdown, so long as the word WOOL is used along with each listed breed…

This is clearly laid out in the following extract from the EU labelling legislation FAQ:-

3. FIBRE NAMES AND COMPOSITION

3.1 Different breeds of sheep provide different qualities of wool. For example, generic wool differs from selected wool such as ‘merino’. Consumers, as well as breeders and mills, would appreciate seeing the composition of knitted fibres described more precisely. Would additional labelling be possible? Could terms such as‘Merino’, ‘Blue faced Leicester’ or ‘Wensleydale’ be used in the labelling of woollen products?

Textile products marketed in the EU need to have a fibre composition label or marking which shows the composition using the fibre names listed in Annex I. In the case of woollen products, the word ‘wool’ has to appear on the product (Annex I, point 1). Terms such as ‘Merino’ or ‘Blue faced Leicester’ are not listed in Annex I, so it is not enough to use breed names alone, without the word ‘wool’. However, the Textile Regulation allows additional labelling, so a company can, if it wants, provide further information on the label, as long as that information is not misleading or deceptive for the consumer. If the manufacturer wants to give additional information, this information must be displayed separately (Article 16.2), e.g. 100% wool – merino.

Consequently, I can list my new Devonia Yarn range on the label as 50% Exmoor Blueface Wool 30% Bluefaced Leicester Wool 20% Wensleydale Wool (100% Wool) This is, in fact, far more accurate than the legislation requires.

However, this term – 100% Wool – is also where the legislation becomes confusing. Quite literally the wool is being pulled over our unsuspecting eyes! Beware the Wolf in Sheep’s clothing, or more accurately the hair masquerading as wool!

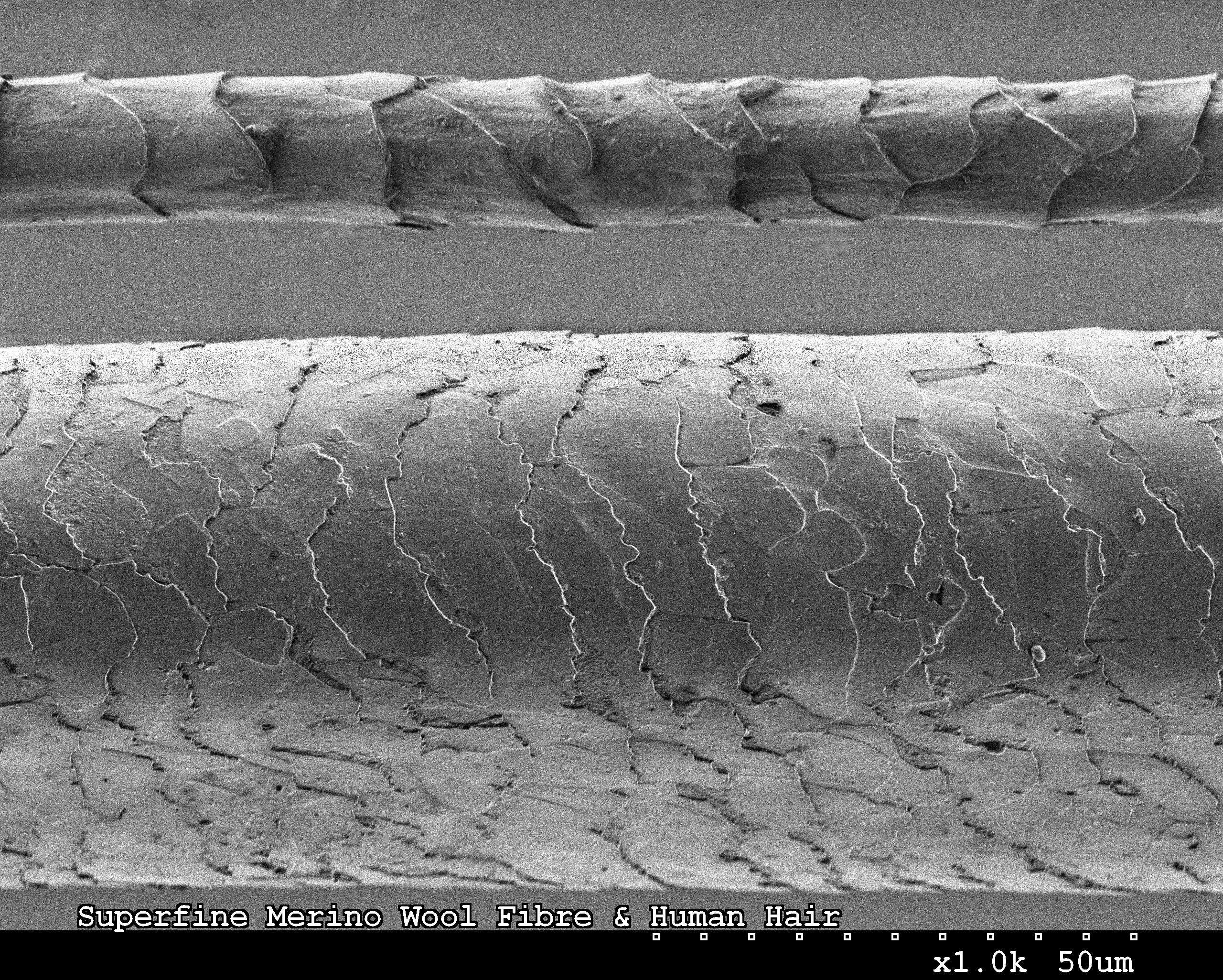

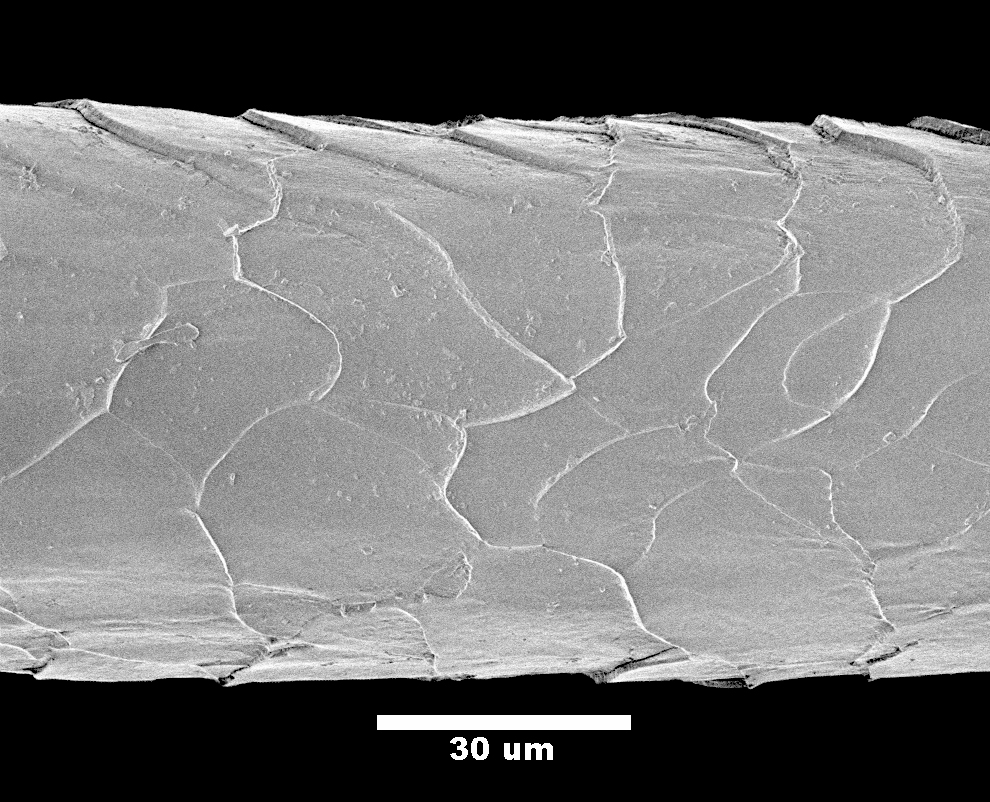

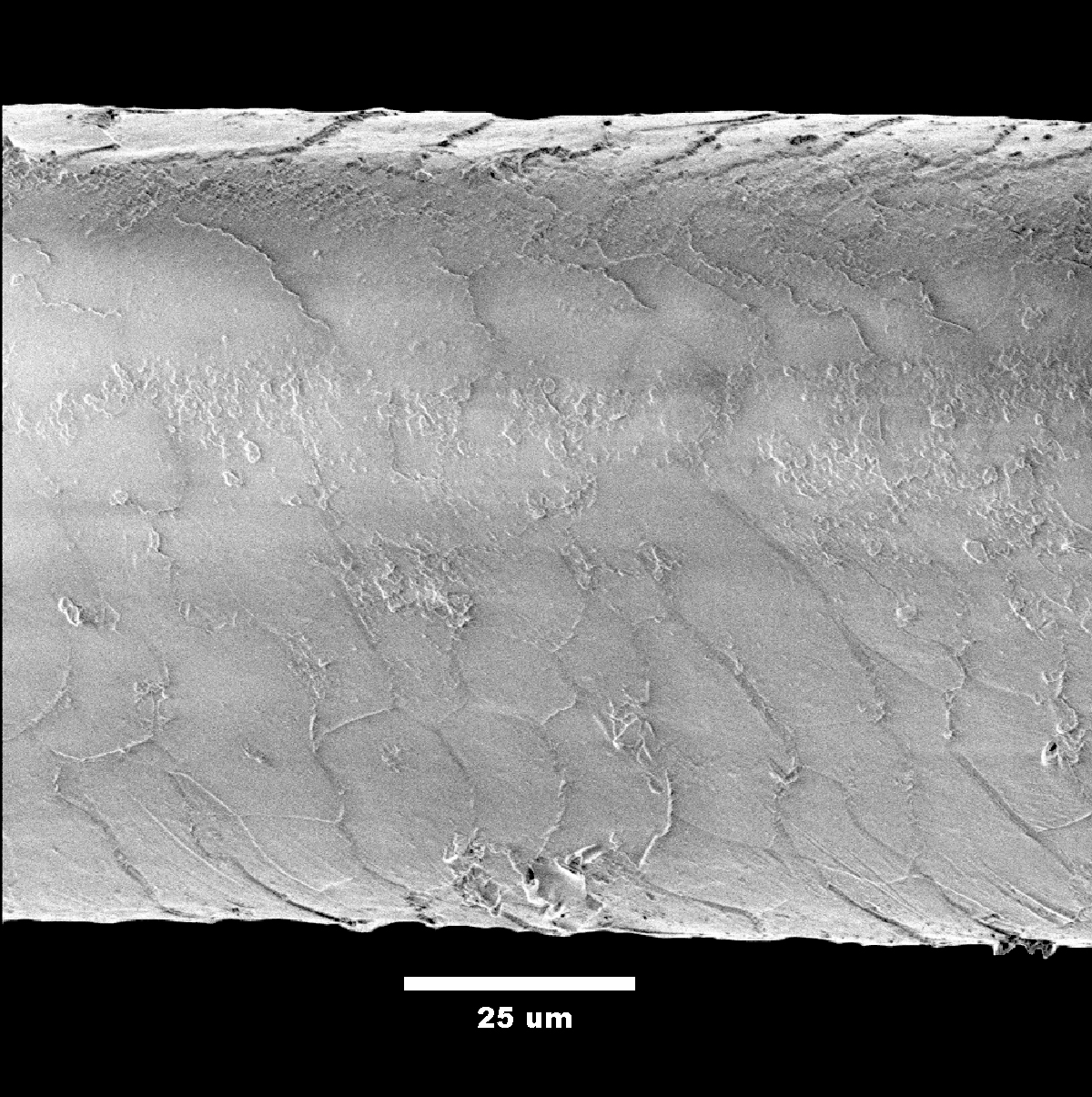

To be clear about what is meant by “WOOL” in the legislation and what is allowed to be called wool, we need to get out the microscope and study the detail in the legislation. Consider this:-

Q: When is wool not wool? A: When it is an Otter

Let’s start at the beginning… if I said raise your hands if you think Wool comes from sheep, I think I would get a 100% hands up, however, according to the European Legislation:

(Article 8 and Annex III of the EU Regulation)

“The fibre name ‘wool’ can be used to describe either fibre obtained from sheep’s or lambs’ fleeces or a mixture of such fibres and certain fine animal hairs (viz alpaca, llama, camel, cashmere, mohair, angora, vicuna, yak, guanaco, beaver, otter)”

Otter?! I hear you cry; well it would appear the EU legislation has turned the fibre world on its head.

I remember my Fibre/Spinning technology lecturer describing the different fibre classes especially animal fibres “Wool is from a sheep and not to be confused with other animal fibres such as Alpaca as that is hair!” or Otter. These fibres are from animals and are classed as hair! This was drummed into to me at university. The term “Wool” is universally accepted as fibre coming from sheep. Even the listing in the Textile Bible better known as the “Textile Terms and Definitions” published by the Textiles Institute states:

“WOOL : (1) The fibrous covering of a sheep (Ovis aries).”

To be fair the Textile Terms and Definitions does refer you to look at Hair

“HAIR : Animal fibre other than sheep’s wool or silk. Note: It is recognized that this definition implies a distinction between sheep’s wool and the covering of other animals, notwithstanding the similarity in their fibre characteristics…It seems desirable in the textile industry, however, to avoid ambiguity by confining the term wool to the covering of sheep and to have available a general term for other fibres of animal origin. Normally the less widely used are known by name e.g. alpaca, mohair, etc but collectively they should be classed as Hair”

All true, unless you are abiding by the EU legislation which has created a totally different use for the term wool.

So why has the term wool been changed and who is directing this legislation? My assumption is that it’s industry-led, but who does it benefit to change the term to include any animal fibre? I believe this change enables processors and producers to use every grade of available fibre, including the poorer coarser grades of HAIR, magically stir it up and call it WOOL. Which when you look at it from a commercial point of view makes total profitable sense, but from a consumer and small scale producer’s point of view seems both wrong and very misleading.

Sadly the trend towards legislation that benefits big business and further muddies the water for consumers is not just confined to classing animal fibre types incorrectly.

Pure Wool

The word ‘Pure’ is often attached to a fibre. What does this mean? I would expect Pure to mean exactly that, but given the wide parameters allowed for what wool can contain, you cannot guarantee it is what you are in fact getting. So, when we look at a label and see 100% Pure Wool, we now know that this in fact could be 100% Pure Otter, poor Otter, or 100% Alpaca (better known as the coarse nasty short stuff we can’t get rid of… I know, let’s call it WOOL). The lack of clarity around the labelling of wool has a direct knock-on consequence for what is meant by ‘Pure’. Article 7 of the EU Legislation is quite revealing about the use of the term ‘pure’:-

Article 7

9. A textile product may be described as ‘100%’, ‘pure’, or ‘all’ only if it is composed exclusively of one fibre type. No other similar expressions may be used. It is not, however, compulsory to use these terms when a product is so composed and, for example, a 100% cotton garment may be described simply as ‘cotton’.

Other Impurities Allowed but not Listed on the Label

Looking deeper into the legislation there are also areas which do seem rather biased towards aiding the industry. This falls within the category of contamination and what does not have to be detailed on the label, but can legally be in the textile even within a so called pure textile. This is detailed in Article 7 part 10.:

10. A textile product described by one of these terms may contain:

a. up to 2% of other fibres which are accounted for by inadvertent impurities or, in the case of a product where the final formation of fibres before spinning is determined by a carding process, 5% of the weight of the product. (In relation to wool textiles, for example, a woollen product may be indicated as ‘100%’, ‘pure’ or ‘all’, provided that it does not contain more than 5% by weight of inadvertent impurities);

This means that during the production of a textile 2% of impurities are allowed and in the case of carding up to 5% is allowed, which I feel is rather extreme.

I run a carder for our production, and know that when you run a carder at the very beginning, if there has been no clean down, you will get an initial cross contamination of fibres in the first doff (first portion of a run) and maybe in excessive situations you will get up to 5% contamination. After that you will get pretty much 100% pure raw material, apart from any stray vegetation still in the fibre. But what this legislation allows is for a processor or producer to continue the whole run after the initial cleaning purge to run with 5% undefined, unidentified fibre. This allows a producer to throw into the mix 5% of whatever they like; all the rubbish, all the waste, all the shoddy! But it is only 5% you say, yes, but look at the logistics if you can add to your Bluefaced Leicester Wool (Expensive) 5% Acrylic waste (Worthless) it makes total economic sense, especially when you are dealing with 100s of tonnes of wool. You can use many tonnes of worthless waste… good business? No, bad practice and legislation which makes it legal.

Now say we have a jumper labelled 100% Pure Wool which we know may not contain any sheep fibre and has around 5% unclassified fibre waste or something cheap. There is also an extra 2% figure for use of fibre to control antistatic effects. This would be an engineered low friction fibre (man-made / synthetic) to reduce the antistatic effects of primarily Hair, but also used for fine sheep wools. Personally I prefer to use a bio-degradeable water soluble solution to control static, but in mass production it does occur and this type of anti-static fibre is used and can also reduce the wool content.

Beware the Mixed Fibre Label

Frequently on textile labelling you will see the term “Mixed Fibres”. This mixed fibre tag refers essentially to waste fibre and/or shoddy (reclaimed textile fibres). Reclaimed fibres will consist of anything and everything as old textiles are quite literally shredded back into a workable fibre mass and will include natural fibres animal/plant and synthetics and man-made fibres. On one hand this is good and I fully support the use of waste and reclaimed fibres. What I do object to is a garment being called a wool jumper when it contains 30% mixed fibres. The mixed fibre blend is there for cost and is an inferior fibre and will not enhance the garment in terms of handle, performance or longevity. It is totally legal to state these mixed fibres on a textile label and since it’s impossible to provide the actual accurate mix of fibres, the generic “Mixed Fibre” tag is allowed. If the garments’ yarn has been blended with wool and mixed fibre, then the known main fibre ingredient can be listed as follows: 70% Wool and 30% mixed fibres. The only reason this practice exists is to lower the cost of yarn and hence garment manufacture.

The EU Legislation states:

“Examples of cases where the terms ‘mixed fibres’ or ‘unspecified textile

composition’ may be used are in substandard and job lots, e.g. scrap yarn

mixtures. The exact fibre composition of such yarns can only be determined by fibre analysis which would be impracticable on grounds of cost. In such cases it is permissible to describe the product as ‘mixed fibres’ or ‘unspecified textile composition’, or alternatively, where it is possible to determine a minimum percentage of the main fibre, for example cotton, to describe the product as ‘mixed fibres, 45% cotton’.

Another point worth noting is that even if the label does denote a percentage of mixed fibre and then names the other fibres and their percentages, do not assume that these fibres have been blended into the mix from a good quality stock. This can indicate that a portion of the recognisable fibres in the 100% mixed fibre mass can be identified and therefore listed, but these fibres making up the yarn have been reclaimed and or are waste fibres of a poorer quality. Sadly EU legislation does not require that these fibres are labelled to indicate that they are from a reclaimed or scrap source. Therefore ‘legally’ I can use 100% scrap/reclaimed fibre with a 50% Wool, 20% Acrylic and 30% Mixed Fibre where the Wool and Acrylic can be identified in the mass, but the remaining fibres cannot!

The EU Legislation states:

“A similar method may be used to describe products made from reconstituted fabrics. Where it is possible to determine the minimum percentages of the main fibres in such fabrics, the names of these fibres and their minimum percentages may be specified, e.g. 40% wool, 35% polyester, 25% mixed fibres”.

One final note is the tolerance given to the composition on the label. This can be subject to a +- 3% of the named constituents. Of all the legislation this makes sense, as due to the production methods employed in textile manufacture this can vary slightly so some leeway must be given, but I feel the consumer should be made aware of this.

Hiding behind the Wool Title

What is lacking from the legislation and does require a healthy clean up, are the misleading titles retailers use for textiles. It is legal to call a jumper a Wool jumper even when wool accounts for only 30% of the textile. I feel the title of a textile should only be called by a fibre type if the fibre percentage is 50% or more of the finished textile. What strikes me as the worst culprit in this laxness around percentages is that manufacturers can put a completely pointless 5-10% of a fibre into the textile just so that it can be called by that fibre name. 7% Alpaca doesn’t make an Alpaca Jumper!

The only positive I can see is that maybe with Brexit the UK can have an improved, clearer and fairer labelling legislation… dream on, John.

Image Credits:

European Union Flag by Yanni Koutsomitis and released under Creative Commons 2.0 License through Flickr

Otter photographed by Airwolfhound from Hertfordshire at the Shepreth Wildlife Park released under Creative Commons 2.0 License through Wiki Commons

Microscopic images of different types of wool and hair by CSIRO released under Creative Commons 3.0 License through Wiki Commons